tapered end mills are used for

For ultra-deep milling within a part Long Reach Tapered End Mills are optimized to deliver pinpoint accuracy Runner Cutter A solid carbide tool used primarily in the mold tool and die industry as a solution to mill channels in molds. Aside from the namesake operation it performs on a part a chamfer mill can be used for several machining operations including beveling deburring countersinking and spotting.

The sharp tips of the end mills are used to cut through narrow paths while the wider bottom is used for larger cuts.

. They are three flute square end with a 30 helix. Conical mills are available in angles of. An endmill bit is a helical rotating cutting tool that can be used for milling operations.

Tapered End Mills are center cutting 3 flute high speed steel tools designed for side milling contouring and machining angled slots. By using a tapered end mill the cross sectional area is larger than a straight end mill of the same tip diameter creating a much stronger end mill that is less likely to bend while milling. They are used in several die and mold applications.

Also known as taper degree end mills theyre often used to machine angled slots in dies and molds. 10-degree taper end mill. This tapered end mill is best for especially sharp edges and corners because of its radiuses.

They are generally used in die-casts and moulds. 20-degree taper end mill. Tapered end mills with a flat tip also called tapered end mills with square end.

Each end mill has flutes on its cutting head that carry the removed material away from the workpiece to prevent damage to the end mill or workpiece. End mills with three flutes provide better chip clearance for high- volume high-speed plunge slotting and roughing cuts. Solid carbide models are 100 precision ground and inspected to insure complete uniformity and reliability required in the precision mold industry.

Tapered end mills are centre-cutting tools that can be used for plunging and are designed to machine angled slots. Chamfer Mill for Beveling. Cobalt Steel Tapered Square End Mills.

Compared with straight reach end mills tapered reach end mills have the following pros and cons. 30-degree taper end mill. All are center cutting allowing plunge cuts into a surface.

The tapered profile of this Helical Solutions End Mill is engineered for optimal performance in light profiling and mold and die finishing applications. Different end and flutes are required by different machining situations. There are many types of end mill cutters which are defined by their design geometries.

They are often referred to as milling bits or router bits. Ideal for use in die cast dies molds. When it comes to Tapered Tapered End Mills you can count on Grainger.

They are predominantly used on CNC and manual milling machines but can also be used on router and drill press. These are also known as Tapered Degree End Mills having a conical cutting head that is wider at the base than the tip. Fully stocked in 4 and 5 flute options with a variable pitch geometry for reduced harmonics and increased feed rates this tool is coated with our Aplus coating for improved tool life and increased edge strength.

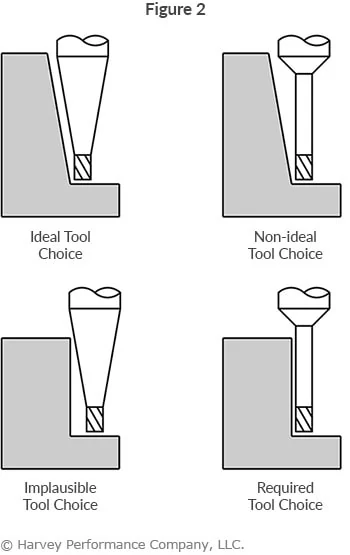

Perfect for 3D machining jobs like molds rapid prototyping models and other other precision parts processing these Tapered ball nose bits can do the best. There are 2 flutes 3 flutes 4 flutes and 6 flutes taper end mill. Reduced clearance Not plausible for use in certain situations.

Tapered End Mills We are Manufacturer and Exporter of Tapered End Mills in India made up of High-Speed steel which is basically used for side milling contouring and machining angled slots. Tapered end mills with a ball tip also called tapered end mills with ball nose end. They are used on computer numerical control CNC or manual milling machines to create parts with complex shapes and features such as slots pockets and grooves.

The type of end mill chosen depends on the material being milled as well as the task being performed. 40-degree taper end mill. Tapered end mills are used on CNC or manual milling machines for die- and mold-machining applications and for milling channels with a taper angle.

About MSC Events Press. They are used specifically for designed parts that require an angled side wall. Taper mills or conical mills produce grooves holes or milled sides with a sloped angle.

The terms chamfer and bevel are often used interchangeably. Supplies and solutions for every industry plus easy ordering fast delivery and 247 customer support. Tapered end mills are designed with a cutting edge that tapers at the end.

According to the included angle of the flute taper there are some commonly used taper end mill. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece. 5-degree taper end mill.

025 05 075 10mm Cutting Length. Ball end mills have rounded tips and are used to mill 3D shapes or rounded grooves. For perfectly vertical walls you will need to use a.

There are two types of taper end mills manufactured from high-speed steel HSS or solid carbide. Coming with 4x 2-Flute tapered ball nose end mills Shank Diameter. Increased tool strength Reduced tool deflection Less chatter better finish Higher speeds and feeds capability Increased productivity.

This singular tool can provide many cost-saving benefits to machinists.

Solid Carbide 2 Flute Tapered Ball End Mills Sdk Tool Supply

Osg Tapered End Mill Cobalt Bright Uncoated 7 Taper Angle Per Side 1 8 In Tip Dia 3 Flutes 35dl87 5964700 Grainger

Basic End Mills Technical Information Msc Industrial Supply Co

Tsc Series Carbide Tapered End Mill 4 Flute Regular Misumi Misumi

Xcan Solid Carbide Ball Nose Tapered End Mills 2 Flute Engraving Router Bits Hrc55 Cnc Engraving Bit Wood Milling Cutter Milling Cutter Aliexpress

Xcan Solid Carbide Ball Nose Tapered End Mills 2 Flute Engraving Router Bits Hrc55 Cnc Engraving Bit Wood Milling Cutter Milling Cutter Aliexpress

Tapered Radius End Mill Gorilla Mill

3 32 Tip X 2 Loc Hss Tapered End Mill 5 Per Side Usa Taper Shank Drill Bits Amazon Com Industrial Scientific

Endmill Design Basics Mastercut Tool Corp

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

End Mills Milling Cutters High Speed Cobalt

Circle Segment Tapered End Mills Emuge Franken Ab

Neck Diameter Archives Harvey Performance Company

Taper Ball End Mill For High Accuracy Rib Slotting Eb4hr Ath Moldino The Edge To Innovation Moldino Tool Engineering Ltd

Taper Ball End Mill For High Accuracy Rib Slotting Eb4hr Ath Moldino The Edge To Innovation Moldino Tool Engineering Ltd

Taper Shank End Mills Abm Tools

Solid Carbide Tapered End Mill At Rs 800 Piece Solid Carbide End Mills Id 4026085812

Solid Carbide 2 Flute Tapered Ball End Mills Sdk Tool Supply